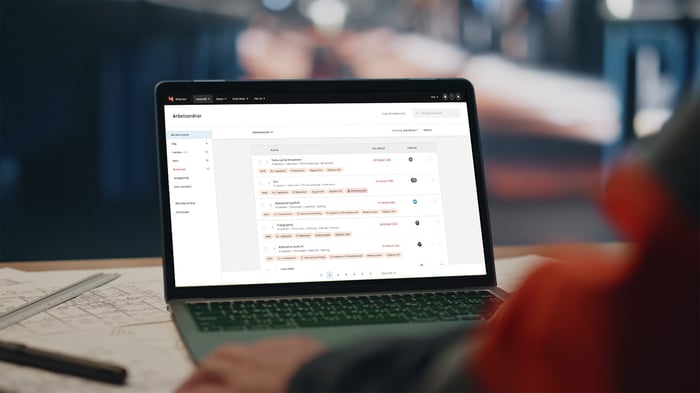

Feature in Mainter

Work Requests

![requests-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/requests-header%20%5BEN%5D.png?width=1200&height=753&name=requests-header%20%5BEN%5D.png)

Our solution

Capture Reported Issues Directly from the Production Staff

The need for maintenance is often identified closest to the production line. That's why Mainter engages your production staff as well, enabling them to register work requests directly at the machine.

Shared Overview

Clear Workflow

Identify Issues

Register Work Requests

Register work requests from either a desktop or mobile device. Label all assets with QR codes to make it particularly easy for production staff to scan the asset and register a work request straight from their phone.

- Scan assets using QR codes

- Attach photos and draw to clarify

- Alert the maintenance department

![create-requests-section [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/create-requests-section%20%5BEN%5D.png?width=1200&height=786&name=create-requests-section%20%5BEN%5D.png)

Enhanced Collaboration

Involve Production Staff

Mainter offers a licensing model that suits everyone in production. With our production boards, operators gain a comprehensive overview of their department, allowing easy access to open work requests, planned maintenance, and major repairs.

Naturally, personal traceability is maintained for maintenance records.

![operational-maintenance-request-section [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/operational-maintenance-request-section%20%5BEN%5D.png?width=1200&height=786&name=operational-maintenance-request-section%20%5BEN%5D.png)

Notify & Automate

Assign Work Requests to the Right Recipient

When a work request is registered, it must be assigned to a specific individual. The recipient receives a notification informing them that a new work request is pending.

Settings for recipients:

- Automated rules

- Creator selects recipient

![assign-request-section [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/assign-request-section%20%5BEN%5D.png?width=1200&height=786&name=assign-request-section%20%5BEN%5D.png)

Plan & Monitor

Create Work Orders from Work Requests

A corrective maintenance can be registered directly from a work request. A work order is created, scheduled, and assigned to a service technician. The individual who discovered the fault and created the work request receives notifications and can track its progress.

![request-work-order-section [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/request-work-order-section%20%5BEN%5D.png?width=1200&height=786&name=request-work-order-section%20%5BEN%5D.png)

Try for Free

Want to Try Mainter?

We’ll help you get started with our mobile maintenance system – quickly and easily, with no fees or commitments.

Features

The Maintenance System That Simplifies Your Everyday Work

A Maintenance System with Everything You Need

Mainter future-proofs your maintenance operations with a set of powerful features – all thoughtfully designed and easy to use. With a mobile maintenance system, your maintenance and production teams can collaborate seamlessly, ensuring nothing slips through the cracks.

Features Work Orders

Overview, prioritize and check off all preventative and corrective maintenance.

![work-orders-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsordrar/EN/work-orders-header%20%5BEN%5D.png?width=600&height=377&name=work-orders-header%20%5BEN%5D.png)

Features Work Requests

Log all issues where they happen – right on the floor – using Mainter’s mobile app and QR codes.

![requests-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/requests-header%20%5BEN%5D.png?width=600&height=377&name=requests-header%20%5BEN%5D.png)

Features Asset Management

Register assets, machinery, and properties in an instant, using drag-and-drop technology.

![assets-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Objekthantering/EN/assets-header%20%5BEN%5D.png?width=600&height=377&name=assets-header%20%5BEN%5D.png)

Features Spare Parts

Ensure efficient spare part management, keep track of what's in stock, and link them to the appropriate work orders.

![spare-parts-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Reservdelshantering/EN/spare-parts-header%20%5BEN%5D.png?width=600&height=377&name=spare-parts-header%20%5BEN%5D.png)

Features Analytics

Review the time and costs associated with your maintenance activities and make informed decisions based on actual analytics.

![statistics-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Statistik/EN/statistics-header%20%5BEN%5D.png?width=600&height=393&name=statistics-header%20%5BEN%5D.png)

![work-orders-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsordrar/EN/work-orders-header%20%5BEN%5D.png?width=960&height=603&name=work-orders-header%20%5BEN%5D.png)

![requests-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Arbetsbeg%C3%A4ran/EN/requests-header%20%5BEN%5D.png?width=960&height=603&name=requests-header%20%5BEN%5D.png)

![assets-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Objekthantering/EN/assets-header%20%5BEN%5D.png?width=960&height=603&name=assets-header%20%5BEN%5D.png)

![spare-parts-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Reservdelshantering/EN/spare-parts-header%20%5BEN%5D.png?width=960&height=603&name=spare-parts-header%20%5BEN%5D.png)

![statistics-header [EN]](https://mainter.com/hs-fs/hubfs/Hemsida/Funktioner/Statistik/EN/statistics-header%20%5BEN%5D.png?width=960&height=629&name=statistics-header%20%5BEN%5D.png)

Reviews

What Our Customers Say

Daniel Bergström

Derome Timber

Helen Tuneld

Blentagruppen

Rikard Carlsson

ShoreLink Terminal

Simple From the Get-Go

Get Started Effortlessly, Enthusiastically, and Quickly

We often hear how easy it is to get started, and how Mainter is perceived as an intuitive and simple maintenance system. Here are our four steps – from first interest to strategic success for your maintenance department.

Interested

Lay the Foundation

Engage Your Team

Strategic Success

Deepen your understanding with a planning calendar, record downtimes, and monitor costs. Congratulations – Mainter is now your strategic maintenance system!

Learn More

The Future of Maintenance is Limitless

Articles

What is CMMS? A guide to CMMS software and systems

Articles

Optimize Daily Maintenance Management in Your Facility

Articles

8 reasons why your maintenance costs are skyrocketing

Articles

How to improve your maintenance planning and resource optimization

Articles

How to measure and reduce costs in your maintenance

Articles